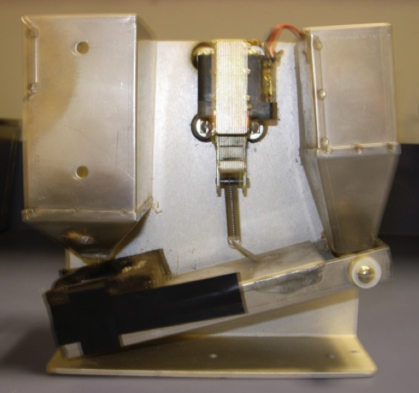

Ralph Gerbrands Company Grain Hopper/Pigeon Feeder 1950s

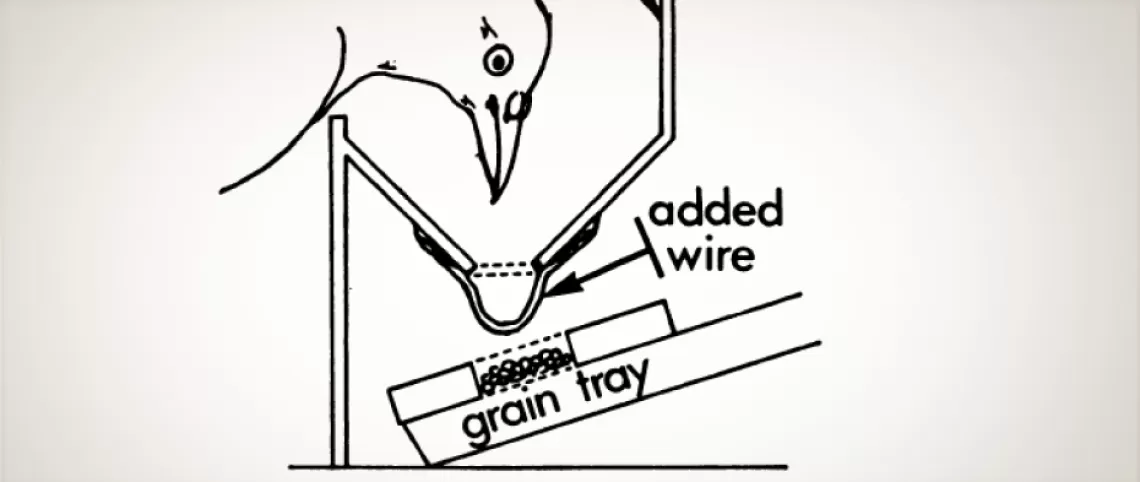

A pigeon feeder similar to this one was described by Ferster and Skinner (1957) in their comprehensive encyclopedia of reinforcement schedule performance, Schedules of Reinforcement. Grain is (or pigeon food pellets are) placed in the vertical bin. The vertical bin in turn funnels the food into a horizontal tray that is attached on its upper surface to an electromagnet. Operating the magnet raises the tray such that a small opening into the tray (on the left side in the photo) is raised in line with an aperture through which the pigeon can place its beak and pick out the morsels of food for as long as the hopper is held in the “up” position by the electromagnet. When the magnet deactivates, the hopper falls to its default position, making it impossible for the pigeon to get more grain before the next reinforcement cycle. The lead weight on the rear of the horizontal tray was intended as a counterweight. The aperture is behind the black rubber on the left side of the horizontal tray; the black rubber prevents metal to metal contact when the feeder is raised into the up position.

A pigeon feeder similar to this one was described by Ferster and Skinner (1957) in their comprehensive encyclopedia of reinforcement schedule performance, Schedules of Reinforcement. Grain is (or pigeon food pellets are) placed in the vertical bin. The vertical bin in turn funnels the food into a horizontal tray that is attached on its upper surface to an electromagnet. Operating the magnet raises the tray such that a small opening into the tray (on the left side in the photo) is raised in line with an aperture through which the pigeon can place its beak and pick out the morsels of food for as long as the hopper is held in the “up” position by the electromagnet. When the magnet deactivates, the hopper falls to its default position, making it impossible for the pigeon to get more grain before the next reinforcement cycle. The lead weight on the rear of the horizontal tray was intended as a counterweight. The aperture is behind the black rubber on the left side of the horizontal tray; the black rubber prevents metal to metal contact when the feeder is raised into the up position.

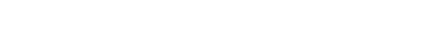

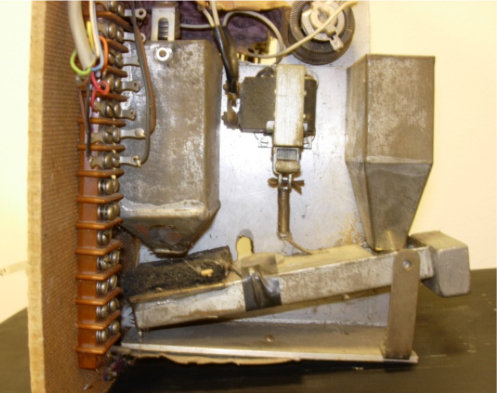

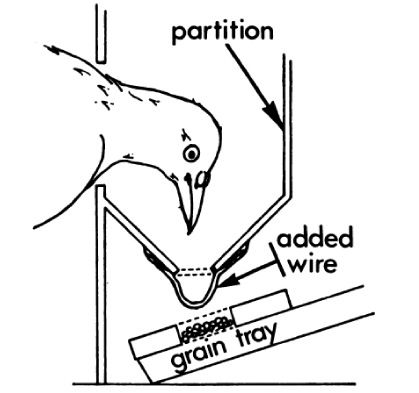

Device to Prevent Stealing from Gerbrands Feeders

A recurring problem with the Gerbrands type feeders was that some pigeons, those with long thin beaks in particular, could stick those beaks into the aperture and “steal” grain when the food tray was in the lowered, deactivated condition. Such behavior not only made for a heavy pigeon, but it was quite disruptive to the experiment because the pigeon’s behavior was controlled not by the stimuli being presented but by the grain hopper. A. Charles Catania developed a simple solution, described in a brief note in the Journal of the Experimental Analysis of Behavior and shown in the diagram accompanying this description. A photograph of an actual antitheft device, from one of Catania’s own chambers, is shown to the right of the diagram. The hopper aperture has been removed from the apparatus and turned upside down in the photograph to clearly show how the antitheft device was assembled. Thus the large opening on the left side of the aperture assembly is where the pigeon would stick its head to access grain through the small aperture at the top of the assembly. A piece of wire was attached to either side of the top part of the aperture assembly (either with screws, as shown here, or simply by soldering it to the chassis. The wire was bent such that it formed a “U.” When the hopper was raised, the wire was covered and the pigeon could access the grain without obstruction. But, when the hopper was deactivated and lowered, the pigeon could not reach the grain and close its beak around it because the beak encountered and was prevented from closing by the wire.

Problem solved!

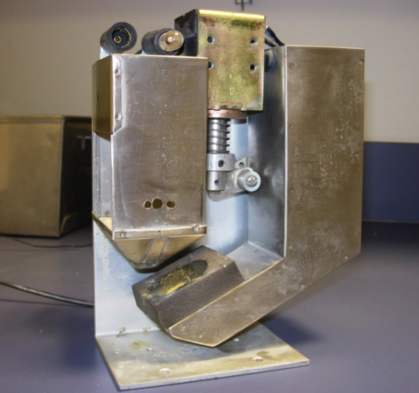

Ralph Gerbrands Company Grain Hopper/Pigeon Feeder 1970s

This hopper functions similarly to the earlier model also on display. The primary differences are that instead of a lead counterweight, this model has a spring loaded counter action mechanism at the back side of the horizontal tray and the solenoid operates off of 28 volts dc rather than 110 volts ac.

This hopper functions similarly to the earlier model also on display. The primary differences are that instead of a lead counterweight, this model has a spring loaded counter action mechanism at the back side of the horizontal tray and the solenoid operates off of 28 volts dc rather than 110 volts ac.

Lehigh Valley Electronics Grain Hopper/Pigeon Feeder

The Gerbrands-designed feeders were subject to food getting caught in the aperture where it was funneled from the vertical hopper to the horizontal tray. When this happened, the horizontal tray would empty and not refill, functionally placing the subject on extinction. A second problem with the Gerbrands feeders is that spilled grain could accumulate under the horizontal tray such that it could not fully drop to its default location. When this happened, the pigeon could continue to access the hopper even though it was not raised by the electromagnet, with the accompanying loss of control over the operant responding. The Lehigh Valley Electronics feeder eliminated these problems. The hopper/tray combination was replaced by a single “angled-L” hopper that swung into the “food accessible position” when the electromagnet was operated. The inactivated, default position, was such that the hopper swung to apposition that made unauthorized access to the hopper impossible.

The Gerbrands-designed feeders were subject to food getting caught in the aperture where it was funneled from the vertical hopper to the horizontal tray. When this happened, the horizontal tray would empty and not refill, functionally placing the subject on extinction. A second problem with the Gerbrands feeders is that spilled grain could accumulate under the horizontal tray such that it could not fully drop to its default location. When this happened, the pigeon could continue to access the hopper even though it was not raised by the electromagnet, with the accompanying loss of control over the operant responding. The Lehigh Valley Electronics feeder eliminated these problems. The hopper/tray combination was replaced by a single “angled-L” hopper that swung into the “food accessible position” when the electromagnet was operated. The inactivated, default position, was such that the hopper swung to apposition that made unauthorized access to the hopper impossible.